For any hardware designer, power consumption control is a big challenge. Lower the power consumption of your product higher the success rate. For a battery operated devices like mobile, tablet and other smart devices power consumption is a critical specification. One critical component in this power consumption/wastage across the board is regulator. Power from the main source like battery, usb power is distributed across the board using regulators. Regulators can either step-up or step-down the input a DC voltage. Based on our requirement we choose a regulator type.

Regulators used in embedded hardware boards can be mainly classified as linear and switching regulators. There are several sub classifications in linear and switching regulators which we will discuss later. For now let us calculate the power dissipation calculation across Linear and switching regulator. For this we will take an example of devices from Linear technologies.

Linear Regulator: LT3014B

Switching Regulator: LTM8020

Power Dissipation calculation for LT3014B

I/P voltage range: 3V-80V

O/P voltage range - 1.22V-60V

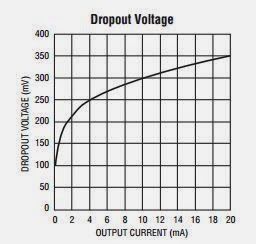

Dropout voltage - 350mV

For a linear regulator, as the output current from the regulator increases, drop out voltage increases which is shown in the graph below from datasheet of LT3014B

Let us assume i want a output voltage of 5V @20mA from LT3014B. To achieve this output, minimum input required is 5.35V. Let us assume, we are providing a input of 7.4V which is Li-ion standard battery pack voltage.

The power dissipated across the linear regulator is (7.4-5)*20m = 48mW

If the input is 50V and output is 5V, then power dissipated is (50-5)*20m = 0.9W

So, we can clearly see that as the difference between input and output is increasing in a linear regulator, power dissipation across regulator is going high. Also, imagine a case where input to output voltage difference is low but current is in amperes, in this case also, power dissipation across linear regulator is very high.

Important note: If the input to output voltage difference is high, or if the current output from regulator is high, power dissipation across linear regulator is very high in which case heat dissipation is high. We may need a huge heat sinks if we use linear regulators in such cases. Also, power is unnecessarily wasted.so, we have to go to switching regulator in these cases.

Power Dissipation calculation for LTM8020

To calculate power dissipation across switching regulator LTM8020, we have to take above graph into consideration. Let us assume my load is drawing 100mA for a input of 24V at output of 5V. In this case, from the graph efficiency is ~82%.

For above requirements, output power = 5v *100mA = 0.5W

Input required power = output/effeceincy = 0.5/0.82 = ~0.6W

So, power dissipated across LTM8020 is, 0.6-0,.5 = 0.1W

Important note: If either the input to output voltage difference is high, or if the current output from regulator is high, power dissipation across switching regulator is less in which case heat dissipation is less. We may not need a huge heat sinks if we use switching regulators in such cases. Also, power is not unnecessarily wasted.So, we have to go to switching regulator in these cases.

Dropout voltage - 350mV

For a linear regulator, as the output current from the regulator increases, drop out voltage increases which is shown in the graph below from datasheet of LT3014B

Let us assume i want a output voltage of 5V @20mA from LT3014B. To achieve this output, minimum input required is 5.35V. Let us assume, we are providing a input of 7.4V which is Li-ion standard battery pack voltage.

The power dissipated across the linear regulator is (7.4-5)*20m = 48mW

If the input is 50V and output is 5V, then power dissipated is (50-5)*20m = 0.9W

So, we can clearly see that as the difference between input and output is increasing in a linear regulator, power dissipation across regulator is going high. Also, imagine a case where input to output voltage difference is low but current is in amperes, in this case also, power dissipation across linear regulator is very high.

Important note: If the input to output voltage difference is high, or if the current output from regulator is high, power dissipation across linear regulator is very high in which case heat dissipation is high. We may need a huge heat sinks if we use linear regulators in such cases. Also, power is unnecessarily wasted.so, we have to go to switching regulator in these cases.

Power Dissipation calculation for LTM8020

I/P voltage range: 4-36V

O/P voltage range - 1.25-5V

The main factor to consider in switching regulators is efficiency. For a given load current, the efficiency can be calculated from the graph below as from LTM8020 datasheet.To calculate power dissipation across switching regulator LTM8020, we have to take above graph into consideration. Let us assume my load is drawing 100mA for a input of 24V at output of 5V. In this case, from the graph efficiency is ~82%.

For above requirements, output power = 5v *100mA = 0.5W

Input required power = output/effeceincy = 0.5/0.82 = ~0.6W

So, power dissipated across LTM8020 is, 0.6-0,.5 = 0.1W

Important note: If either the input to output voltage difference is high, or if the current output from regulator is high, power dissipation across switching regulator is less in which case heat dissipation is less. We may not need a huge heat sinks if we use switching regulators in such cases. Also, power is not unnecessarily wasted.So, we have to go to switching regulator in these cases.